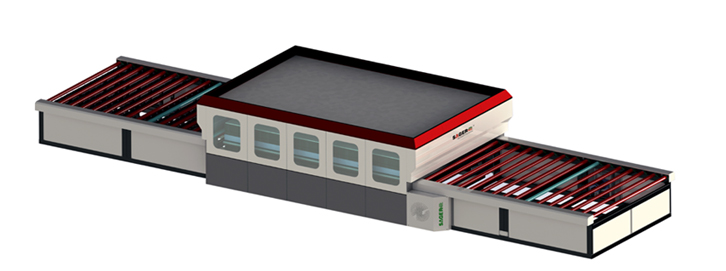

The SZ-ALAM-3725-I is a high-performance glass laminating machine designed for producing laminated glass without autoclave, ideal for PVB and EVA interlayer films. It combines advanced temperature control, precise pressure management, and fully automatic operation to achieve consistent high-quality laminated glass for architectural and industrial applications.

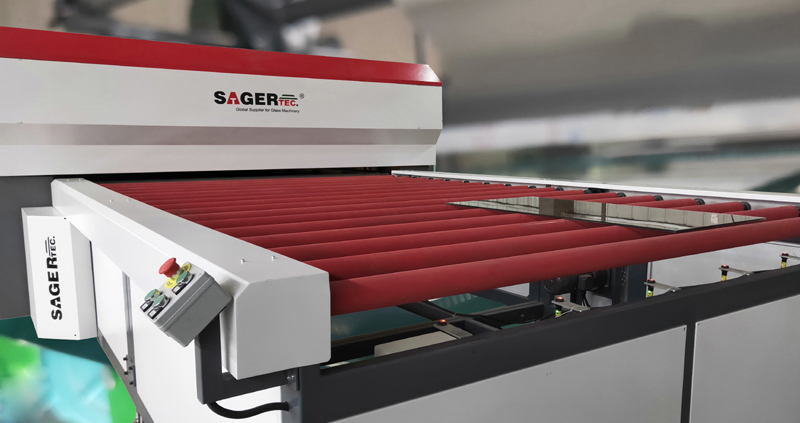

Equipped with a Siemens PLC control system and intuitive touch screen interface, the machine allows operators to easily set and monitor all process parameters. PID temperature regulation ensures accurate and uniform heating, while the frequency-controlled conveyor system provides smooth glass transfer throughout the process.

The entire production cycle — from loading to unloading — is fully automated. Operators only need to load the pre-assembled glass onto the loading table; the machine automatically conveys, heats, laminates, and cools the glass before transferring it to the unloading section. This minimizes manual labor while maximizing productivity.

Thanks to its continuous conveyor design, the SZ-ALAM-3725-I enables high production capacity with cycle times of approximately 10–15 minutes per batch, suitable for both mass production and custom single-piece processing.

Features:

- Non-autoclave laminating system compatible with PVB/EVA films

- Siemens PLC + PID control for precise temperature and process stability

- Automatic loading, laminating, and unloading for labor saving

- Continuous conveyor operation for high throughput and reliability

- Ideal for architectural, safety, decorative, and solar glass production

视频

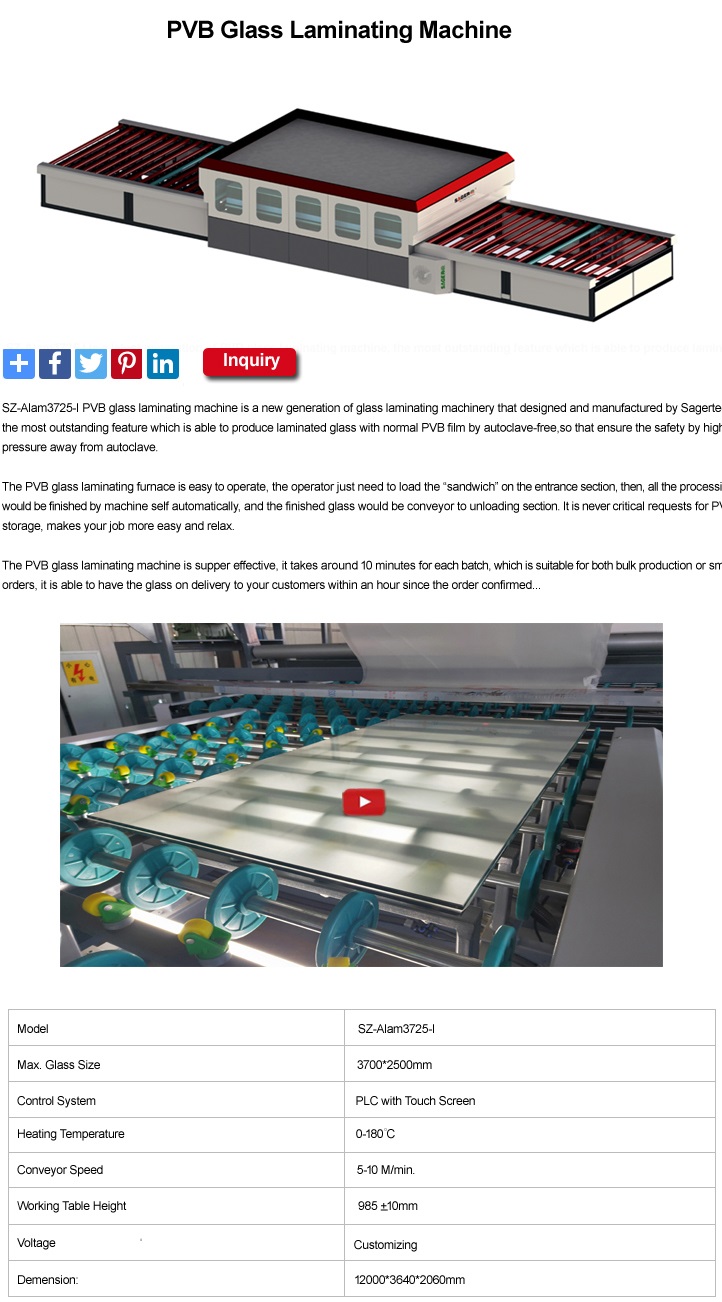

| Model | SZ-Alam3725-I |

| Max. Glass Size | 3700*2500mm |

| Control System | PLC with Touch screen |

| Heating Temperature | 0-160℃ |

| Conveyor Speed | 5-10 M/Min. |

| Working Table Height | 985±10mm |

| Voltage | Customizable |

| Demission | 12000*3640*2060 |