About Non-Autoclave Glass Laminating Machine

08-02-2023

The non-autoclave glass laminating machine is a specialized equipment used for the production of laminated glass. It is used in the manufacturing process of different types of laminated glass such as artistic laminated glass, proof laminated glass, switchable laminated glass, and panel laminated glass. This machine helps in bonding the layers of PVB film and glasses together to make strong and durable lamination . The non-autoclave technology allows manufacturers to create high-end products without using an autoclave but still achieving good performance. It also provides more flexibility in terms of product design by allowing for custom sizes and shapes. With this type of equipment, manufacturers can produce quality products with lower costs compared to traditional autoclave processes.

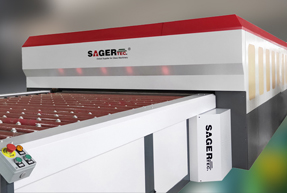

The Non-Autoclave Glass Laminating Machine consists of different ovens and transport rollers for the production line. The laminated glass panels are then moved to the oven where they are heated at different speeds according to the chosen methods. This process does not require an autoclave, making it a more cost-effective operation than traditional methods. After the glass is heated in the oven, it is then transferred to another station where after it is cooled using a well-defined method. The panels are then transported to another station for quality control before they can be shipped out or used in other operations.

Non autoclave glass laminating machines are used to join two or more pieces of glass together in order to create one, stronger piece. The process cycle starts with the application of a heated vacuum on the glasses and layers of PVB (Polyvinyl Butyral) that are placed between them. This is followed by a pressing down on the assembly while ambient air is applied, which helps maintain the original shape . Finally, once all steps are completed, a hardened layer is formed between two pieces of glass that can now be considered as one single entity.The typical autoclave lamination process uses heat and pressure to bond the glass pieces together.

Non-autoclave glass laminating machines use a very different method to join the two pieces of glass. This machine can handle any type of glass thickness and can create a finished laminate with any number of layers. It begins with the lamination cycle ramps up pressure, temperature, and air into the chamber containing the film and two sheets of glass.The Non-Autoclave Glass Laminating Machine is used to laminate switchable glass pannel, touch screen panels and other laminated glass products. It offers an available adhesive films like PVB, PET film and others which meet the processing requirements. This equipment provides continuous production and eliminates manual labor.